Design of Normal Hexane Treatment Unit

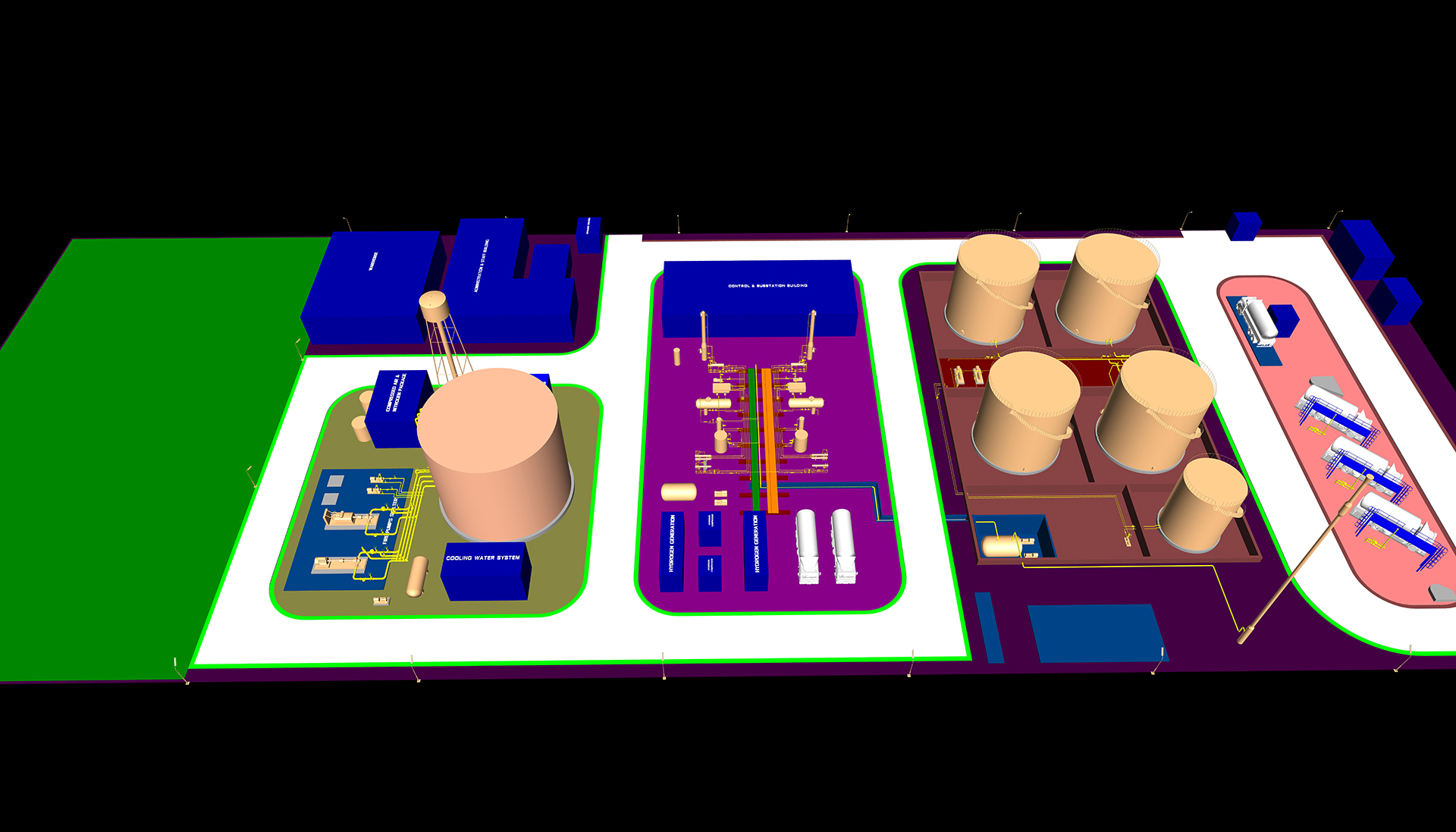

N-hexane is a widely used non-polar solvent that is known for its affordability, safety, and efficient evaporation capabilities. However, domestically produced N-hexane can contain significant amounts of benzene, a toxic material that needs to be removed before the solvent can be used in various applications. Our company's engineers have developed a purification process for N-hexane that involves hydrogenation of benzene, where the existing benzene in the primary product reacts with hydrogen at high temperatures to produce a purified product.

To support the hydrogenation process, our engineers have developed a novel ammonia decomposition process that produces the required hydrogen using the latest methodologies. This process not only improves the overall efficiency of the purification process but also reduces costs and ensures the highest level of safety.

In addition to developing the purification process and ammonia decomposition process, our engineers have designed all the necessary utilities, including water treatment, steam generation, a cooling water system, loading and unloading arms, and required buildings. The detailed design of these utilities ensures optimal efficiency and functionality, while also complying with all relevant safety and environmental regulations.

Overall, our company's successful purification process for N-hexane demonstrates our expertise in advanced industrial processes and our commitment to excellence. Through the use of cutting-edge technology and the ingenuity of our talented team, we have established ourselves as a leading player in the field of solvent purification. We are dedicated to providing our clients with the highest level of service, while also prioritizing safety, efficiency, and sustainability.

Service:

Basic Engineering Services

Project Duration:

6 months

Client:

Sanaat va Sonyaye Eghtesad

Person Hour:

18000 hours