FRW

The Fully Refined Wax Project (FRW) aims to produce fully refined wax from Slack Wax, which can be utilized in cosmetic and health products. By implementing this process, Sepahan Company will be able to enhance the Pour Point quality of the produced base oil. Furthermore, this project will enable Sepahan to add liquid paraffin to its product line, resulting in increased profitability. The successful completion of this project will also lead to continuous improvement in the production and development processes of the dewaxing unit. Although the current production capacity will remain the same, the oil content in the produced wax will decrease by half a percent, while the quality of the base oil will increase.

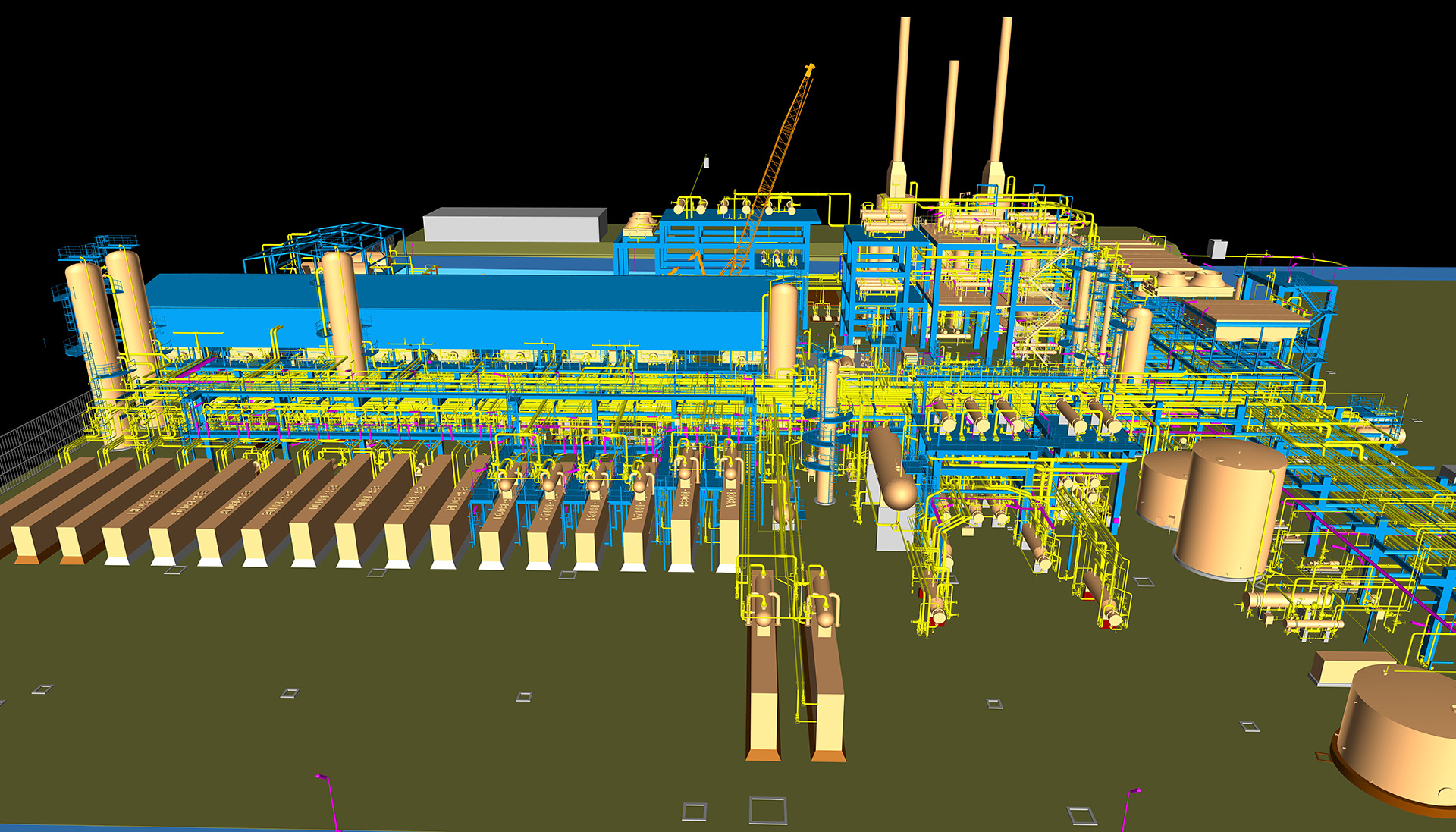

The Basic Engineering Design of the project was conducted by EDL, a Germany-based company. The Technical Engineering Group at Phoenix Oil and Gas Company is responsible for implementing the detailed design, ensuring that the project is executed with the highest level of technical proficiency.

This project is an essential milestone for Sepahan Company, as it will enable the company to expand its product line and increase its profitability. The innovative process developed for the FRW project is a testament to the technical expertise of Phoenix Oil and Gas Company. The project's successful implementation will serve as a benchmark for other companies in the industry, highlighting the importance of continuous improvement and innovation in the pursuit of excellence.

Overall, the FRW project is a testament to the innovative spirit and technical expertise of Sepahan and Phoenix Oil and Gas Company. By enhancing the Pour Point quality of the produced base oil and adding liquid paraffin to its product line, Sepahan is poised to expand its reach and profitability, further cementing its position as a leader in the industry.